Рощин П.В.1, Рогачев М.К. 2, Л.К. Васкес Карденас3, Кузьмин М.И.4, Литвин В.Т. 1, Зиновьев А.М.5

1аспирант, Национальный минерально-сырьевой университет «Горный», Санкт-Петербург, Россия (199106, Санкт-Петербург, В.О., линия 21-я), e-mail: paulforrest@ya.ru; 2профессор, д.т.н., Национальный минерально-сырьевой университет «Горный», Санкт-Петербург, Россия (199106, Санкт-Петербург, В.О., линия 21-я); 3студент, Национальный минерально-сырьевой университет «Горный», Санкт-Петербург, Россия (199106, Санкт-Петербург, В.О., линия 21-я); 4главный специалист, ООО «Газпромнефть НТЦ», Санкт-Петербург, Россия (190000, г. Санкт-Петербург, ул.Галерная, 5А), e-mail: kuzmaxig@gmail.com; 5аспирант, Самарский государственный технический университет, Самара, Россия (443100, г. Самара, ул. Молодогвардейская, 244).

ИССЛЕДОВАНИЕ КЕРНОВОГО МАТЕРИАЛА ПЕЧЕРСКОГО МЕСТОРОЖДЕНИЯ ПРИРОДНОГО БИТУМА С ПОМОЩЬЮ РЕНТГЕНОВСКОГО КОМПЬЮТЕРНОГО МИКРОТОМОГРАФА SKYSCAN 1174V2

Аннотация

Есть много методов исследований керна. Такие как точечный метод, различные методы исследования микроскопии, и т.д. Но есть один большой минус во всех этих методах: мы должны разрушить образец породы (керна). Но теперь мы можем проводить исследования кернов, не нарушая его природной целостности с помощью работы с рентгеновскими сканерами и специальным оборудованием томографии. Вследствие чего мы можем увидеть и описать структуру керна в целом. Результаты данных исследований в виде 3D-моделей помогают выбрать наилучший способ добычи нефти, битума или газа. В работе представлены результаты исследования керна битума и тяжелой нефти Печерского месторождения. Исследование было проведено в лаборатории повышения нефтеотдачи пласта Национальном минерально-сырьевом университете «Горный».

Ключевые слова: битум, томография керна, повышения нефтеотдачи пласта, тяжелая нефть, образования карбонатов.

Roshchin P.V.1, Rogachev M.K. 2, Vasques CardenasL.K.3, Kuzmin M.I.4, Litvin V.T. 1, Zinoviev A.M. 5

1Student of PhD course, National mineral resources university, e-mail: paulforrest@ya.ru; 2Professor, Doctor of Engineering Science, National mineral resources university 3Student, National mineral resources university 4PhD, chief Specialist, LLС «Gazpromneft STC», e-mail: kuzmaxig@gmail.com; 5Student of PhD course, Samara State Technical University.

THE RESEARCH OF CORE SAMPLE OF PECHERSKOE BITUMEN FORMATION BY SKYSCAN 1174V2 MICRO-CT SCANNER

Abstract

There are a lot of methods of core investigation. These may be slice method, different methods of microsope investigations, etc. But there is one big disadvantage in all these methods: we must break, deatroy a sample of rock (core sample). But now we can provide investigations with core samples without breaking – working with X-ray scanners and special tomography equipment. Because of the fact we may see and describe whole structures in the core sample. After that 3D models helps is to find the best way to producing oil, bitumen or gas. There is the investigation of core sample from old bitumen and heavy oil formation Pecherskoe in this article. Investigation has been provided at the Enhance Oil Recovery laboratory in Saint-Petersburg Mining University.

Keywords: bitumen, core tomography, enhanced oil recovery, heavy oil, carbonate formation.

Basic principles of micro-tomography

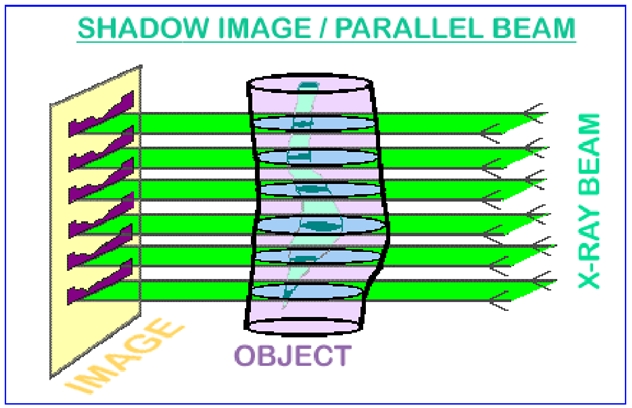

An X-ray (radiography) system produces 2D shadow images of complete internal 3D structures, but in a single 2D shadow projection the depth information is completely mixed. An X-ray shadow image represents a 2D projection from a 3D object.

Pic. 1 – Basic principle of X-ray tomography (SkyScan 1174 manual)

That shows the possibility of this reconstruction on a simple example, an object with only one point with significant absorption in an unknown place. In the one-dimensional shadow line a decreasing of intensity of the shadow of absorption in the object area will be seen (see the next picture). Now we can initialize in the computer memory an empty array of pixels (picture elements) corresponding to possible object is placement [1].

Geology of Pecherskoe bitumen formation

There were a lot of mines at Pecherskoe bitumen formation in Samara. At the 19th century there were produced big amount bituminous mastic from carbonate deposit. It was open-pit and shaft mining (pic. 3). Nowadays there are some formations like lenticular pools paragenetic relative to brimstone.

Pic. 2 – Pecherskoe bitumen mines (photo made by Roschin P.V.)

Percentage composition of bitumen is 6 – 13%, but sometimes – up to 37%. The process of product operations was very simple. After heating of producing asphaltic material from mines asphalt for roads has been produced. There were a lot of mining operations at this oil field at the 19th century.

Core sample scanning and analysis

Authors of this article took a lot of samples of rock during their geological researches at Pecherskoe bitumen mines. Preparing the core-sample was consist of some parts (coring in situ, prepare core samples at laboratory “Enhance oil recovery” in the St-Petersburg State Mining university, extraction of cores, X-ray tests and scanning).

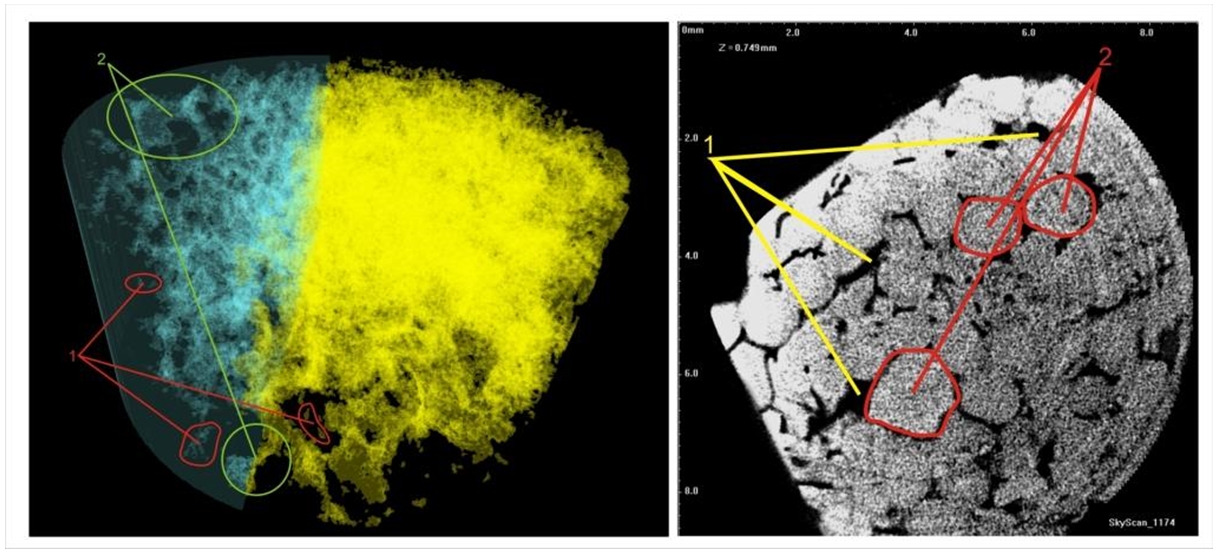

High open porosity (14.32%) signify a lot of fracture-porous channel ways in carbonate rocks of Pecherskoe oil field. According to the results were developed a 3D model of VOI (volume of interest) of core sample for visualization of rock and porous volumes. 3D model has been built in CTvol (SkyScan 1174 software). The authors of this article provided researches of core samples for calculating total pore volume and open pore volume.

Pic. 3 – 3d model of core sample and slice. (1 – non-connected pores, 2 – interconnected pores).

Particular yellow structures are interconnected pore space. There is a lot of interconnected pore space in this sample (14.31%). For analyzing rock structure and accumulation of Pecherskoe formation authors provide special research for demonstration reefogenic history of this formation. There are some remains of corals at pic. 3. Also, black space between them – pore volume, which may contain the bitumen.

The extraction of bitumen

The term “bitumen formation” means a natural bitumen and extra-heavy oil, which are characterized by high viscosity, high density (low API gravity), mixed with a sand or clay and water in a reservoir. Bitumen will not flow unless it’s heated or diluted. Also this mixture includes high concentrations of nitrogen, oxygen, sulphur, and heavy metals. It means, to extract heavy oil from the underground tar sands must be heated, extracted entirely or chemical reagents must be use to reduce the viscosity. That is why Oil Companies needs more capital costs to develop this type of fields.

But because of the fact that bitumen mixture flows very slowly, if at all, toward producing wells under normal reservoir conditions, the mixture must be extracted by strip mining if deposit is on the depth less than 100 meters from the ground or the oil made to flow into wells by reducing the viscosity by injecting steam, solvents, and/or hot air into the sands in case of more than 100 meter deposit depth [3]. These processes can use more water and require larger amounts of energy than conventional oil extraction, although many conventional oil fields also require large amounts of water and energy to achieve good rates of production. In this case we can only reduce the extraction costs, make the transportation cheaper.

But there are natural bitumen that accumulates at the depth 100 meters and more that are not profitable to mine. At this type of deposit we can use the next interesting fact about oil – the dependence between the oil viscosity and temperature. There are a lot of formations with heavy high viscous oils and bitumen like this at Samara region [5].

In situ methods are used to recover bitumen that lies too deep beneath the surface for mining (about 80% of the oil sands in Alberta) [6]. The success of in situ methods depends on the resolution of two major issues: reducing the viscosity of bitumen so that it will flow, and recovering the bitumen from deep within the earth. Overcoming these challenges requires substantial energy and water, and in situ methods are expensive compared to mining. Nonetheless, production of bitumen from in situ projects is already substantial and may surpass that of mining in the future as research develops new methods and technologies for in situ recovery.

- Cyclic Steam Stimulation (CSS) in this method the 300-340°C vapor injection to the bank, heating up the rocks, then fluid is pump in gap for a period of time. Using only one well at all. The process can be done as many time as production rates is profitable.

- Steam Assisted Gravity Drainage (SAGD) uses two parallel horizontal wells. The upper injects the vapor to heat up the reservoir, the lower is pump up the fluid[4].

- Vapor Extraction Process (VAPEX) is the same method as SAGD, but instead of water we are using the special solvent which is more efficient and recyclable.

- Toe to Heel Air Injection (THAI) is combustion process combines controlled combustion with vertical and horizontal wells. The simple equation is: air in, upgraded heavy oil out.

All these in situ methods are developing and upgrading day by day. Now the system SkyScan 1174 allows us to visualize the whole process of heavy oil extraction. The researches of core samples consist of two parts: scanning before the filtration experiments and after. That allows us to see the differences and upgrades of the pore space and a rock. We can use the method of X-ray scanning to understand the efficiency of chemical treatment, polymer flooding etc.

In Conclusiones

The methods of X-ray investigation gave good results. Pecherskoe bitumen formation is not a new field of Russian experience of heavy oil extraction, but it is unique in case of modern types of extraction of bitumen. In nowadays world we cannot imagine the capital costs of Pecherskoe bitumen formation for example. That is why we have to develop the new cheap methods of heavy oil and bitumen extraction and that is why we need to rise to the new level of technical progress to visualize the processes that happens deep down the earth crust and may be even deeper.

References

- SkyScan 1174v2 user guide. Bruker Micro-CT. 2010.

- Sidorov A.A. The history of the discovery of oil in Samara and its significance for the development of the oil and gas industry in Russia. “Samara in the history of Russia.” Issue 4. Materials of interregional scientific conference devoted to the 160th anniversary of the Samara province and the 125th anniversary of the founding of the Samara Regional Local History Museum. PV Alabin. – Samara, 2012. 262 p.

- Ruzin L.M., Chuprov I.F. Technical principles of abnormally viscous oils and bitumens fields development: monograph. / Edited by Tskhadaya N.D., Ukhta: UGTU, 2007. 244 p.

- Max Medina. SAGD: R&D for Unlocking Unconventional Heavy-Oil Resources. The Way Ahead. SPE, 2010. 4 p.

- Roshchin P.V., Petukhov A.V., Vasquez Cardenas L.C., Nazarov A.D., Khromykh L.N Issledovanie reologicheskikh svoystv vysokovyazkikh i vysokoparafinistykh neftey mestorozhdeniy Samarskoy oblasti [Fields of Samara region – study of rheological properties of high-viscosity and waxy oil]. Neftegazovaya Geologiya. Teoriya I Praktika, 2013, vol. 8, no. 1, available at: http://www.ngtp.ru/rub/9/12_2013.pdf

- Alberta Department of Energy. (2007, December). Alberta Oil Sands 2006. Accessed November 3, 2009.

- Andy Burrowes, Rick Marsh, Nehru Ramdin, Curtis Evans (2007)

- Central Intelligence Agency. (2008). Oil – proved reserves. World Factbook. Accessed November 3, 2009.