РОЛЬ НАНОТЕХНОЛОГИЙ В СТРОИТЕЛЬНОЙ ОТРАСЛИ И ЭНЕРГОЭФФЕКТИВНОСТИ ЗДАНИЯ

Научная статья

Асрар Канишка1, *, Окольникова Г. Э.2, Хесам Али А.Р.3, Свинцов А.П.4

1 ORCID:0000-0003-1223-4122;

2 ORCID: 0000-0002-8143-4614;

3 ORCID:0000-0003-0640-9563;

4 ORCID: 0000-0003-0564-3307;

1, 2, 3, 4 Российский университет дружбы народов (РУДН), Москва, Россия

* Корреспондирующий автор (kanshkas[at]mail.ru)

Аннотация

В настоящее время нанотехнологии представлены как инновационная область исследований в современных технологиях, различных отраслях промышленности и высокоэффективных зданиях. Использование нанотехнологий как гибкого явления и их применение в строительной отрасли дало большую стабильность, снизило потребление энергии и улучшило характеристики строительных материалов. В этой статье авторы попытались представить и проанализировать наноматериалы и их применение в различных строительных отраслях. Исследование, проведенное на основе описательно-аналитических методов, показало, что технологии наноматериалов полезны для создания инфраструктуры и эффективно обеспечивают устойчивость окружающей среды.

Ключевые слова: нанотехнологии, новые технологии строительства, накопители энергии в материалах, материалы с нанопокрытием.

ON THE ROLE OF NANOTECHNOLOGY IN THE CONSTRUCTION INDUSTRY

AND ENERGY EFFICIENCY OF BUILDINGS

Research article

Asrar Kanishka 1, * , Okolnikova G.E.2, Hesam Ali A.R.3, Svintsov A.P.4

1 ORCID:0000-0003-1223-4122;

2 ORCID: 0000-0002-8143-4614;

3 ORCID:0000-0003-0640-9563;

4 ORCID: 0000-0003-0564-3307;

1, 2, 3, 4 People’s Friendship University of Russia (RUDN University), Moscow, Russia

* Corresponding author (kanshkas[at]mail.ru)

Abstract

Nowadays, nanotechnology has been presented as an innovative research field in modern technology, various industries, and highly efficient buildings. Using nanotechnology as a flexible phenomenon and its application in the construction industry has given more stability, decreased energy consumption, and improved construction materials’ performance. In this paper, the authors tried to introduce and analyze nanomaterials and their application in the different parts of the building and construction industry. The research, which was done based on descriptive-analytical methods, indicated that nanomaterial technologies are useful for building infrastructure and effectively ensure the environment’s sustainability.

Keywords: Nanotechnologies, building new technologies, materials energy storage, nano-coated materials.

Introduction

Nanotechnology is any nanoscale technology with applications and productivity in chemical, physical, and biological systems of scales ranging from individual atoms (0, 1-100 nm) to submicron dimensions and integrating the resulting nanostructures into larger systems [1]. This technology can also be defined as the design, characterization, production, and use of structures, tools, and techniques by controlling the shape and size of materials at the nanoscale [2]. For the first time, nanotechnology offers tools to develop new industries based on cost-effective and cost-efficient economies. Nanotechnology is extensively used to manufacture polymers with molecular structures, designing computer lathes and modern energy devices. Nanoparticles also play an essential role in manufacturing cosmetics, various coatings and protective equipment, durable clothing, and the leading industries, including construction and materials building [3], [4]. Nano helps produce materials with quality and characteristics to achieve better strength, energy conservation, material life, hygiene, and other construction industries.

Currently, the construction industry has a very competitive and big market due to the availability of a vast range of materials. Although paying attention to products and substances with the most negligible environmental impact is a crucial issue in selecting sustainable materials for the construction industry, other aspects such as beauty, quality, repairing, maintenance capability, easy access, and reasonable costs should also be considered. Zhu and colleagues clearly explained the importance and potential of nanotechnology in building materials and construction in the report called RILEM TC 197-NCM [5], [6]. It has resulted from their research report that the nano has the following potentials to be an innovative, functional, and cheap technology;

- The use of nanoparticles, nanofibers, and carbon nanotubes increases cementitious composites’ strength and durability and leads to pollution reduction.

- It improves the production of thermal insulation materials with a performance10 time commercial current option.

- Production of cheap corrosion-free steel.

- To facilitate coats and thin-film production with the self-cleaning ability and self-color change to minimize energy consumption.

Parvin assessed the various application of nanotechnology in the construction industry and indicated that nanomaterials in the composition of some materials, such as cement, will significantly reduce CO2 pollution. Moreover, the use of performance thermal insulations will result in inefficient use of energy [7].

Methods

This research is based on descriptive-analytical approaches by considering a series of library studies and later comparative-applied methods to present nanotechnology’s practical application in the building and construction industry. For this purpose, first, the main concepts related to nanotechnology have been evaluated and defined. Then, while mentioning this technology’s importance and place in a scientific society, we examined nano’s role in the building industry. Moreover, using the previous researches and experts’ ideas, we analyzed the effects of using building materials in construction and the possibility of their coverage with nanotechnology.

Research Findings

- Application of nanotechnology in the construction industry

The construction industry is an industry that is divided into several sections and, therefore, changes in its elemental occurs very slowly. Strict rules and regulations are characteristic of this industry [8]. The construction industry faces a wide range of challenges, such as nanomaterials’ performance in environmental-related issues, the detrimental effects on human health and safety, and raw materials and their properties. Recent developments in nanotechnology showed that this technology has a promising approach to face many of these challenges. The application of nanotechnology in the building industry includes developing the concept and understanding of cement particles’ hydration. It also provides a framework for the use of nanoscale materials such as alumina and silica and other new nanoparticles, which can improve the characteristics and vital qualities of building materials, especially resistance, durability, lightness, etc. Table (1) summarizes the primary and essential applications of nanomaterials in construction and building materials.

Table 1 – Nanomaterials used in construction materials

| Application Area | Nanoparticle Type | Major Applications |

| Concrete | Silica nanoparticles

Titania nanoparticles Carbon nanotubes |

• Reinforcing mechanical strength

• Self-cleaning • Rapid hydration • Increasing the degree of hydration • Improving the mechanical durability • Crack prevention |

| Concrete | Iron oxide nanoparticles | • Abrasion-resistant

• Weldability • Increasing the compressive strength |

| Asphalt concrete | Zycosoil | • Increased fatigue life

• Higher compaction |

| Asphalt concrete timber | Aluminum oxide nanoparticles | • Increasing serviceability |

| Bricks mortar | Clay nanoparticles | • Increasing compressive strength

• Increasing surface roughness |

| Steel | Copper nanoparticles | • Weldability

• Corrosion resistance |

| Glass | Titanium dioxide nanoparticles (Titania)

Silican dioxide (Silica) |

• Self-cleaning

• Anti-reflective • Fireproof • Anti-dust and anti-fog |

| Paint | Silver nanoparticles (AgNPs)

Titanium dioxide (TiO2) |

• Self-cleaning

• Anti-bacterial • Antistatic • Scratch resistant |

Furthermore, new functions such as energy storage, self-repair, self-cleaning, anti-corrosion capability, and improvement of the main components used to maintain and ensure the building’s health, like structural health monitoring sensors, can be expected from new materials coated with nanoparticles. For instance, in nanocoatings, the possibility of self-cleaning, fire resistance and anti-bacterial in glasses, concrete ability to reduce cracking in compacted concrete, low carbon nanoparticles with high carbide, and other relevant functions have significant results for the construction industry [9], [10].

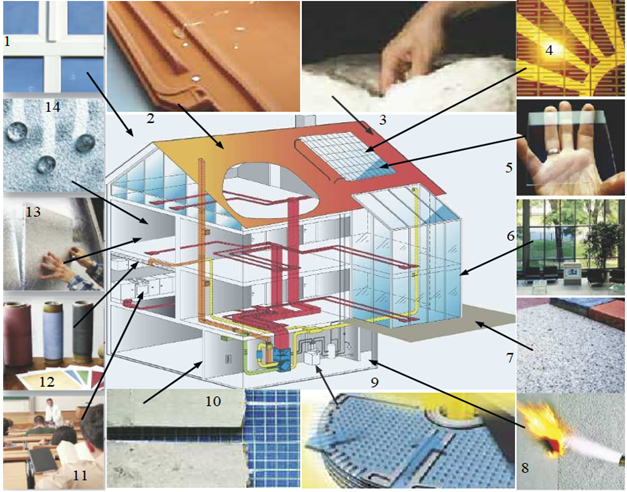

Fig. 1 – Different usages of nanotechnology in construction and building materials:

1 – self-cleaning window (glass); 2 – self-cleaning and decorative roof tiles; 3 – fire-resistant insulation wool for roof insulation; 4 – dye solar cells for regenerative energy supply; 5 – anti-reflective coatings for solar cells; 6 – control of the light and heat flow through smart windows; 7 – soiling-resistant floor panels; 8 – fireproof doors, windows, and cables;

9 – fuel cells for building services; 10 – optimized concrete properties for building structures; 11 – anti-fingerprint and anti-bacterial properties for fittings and furniture; 12 – ceramic foils as a wall covering; 13 – highly efficient facade insulation;

14 – dirt-repellent or self-cleaning facade surfaces

- Windows and glass

About a third of a building’s energy is wasted through windows. For this reason, efforts to reduce energy consumption in buildings are focused on windows [11]. Many studies have been done to find energy storage methods, and the need for energy storage has led to the invention of new types of glass windows in buildings and offices [12]. As a building material for windows and facades, glass is characterized by its high transparency, durability, shape, and color. However, the strong tendency to soiling, annoying reflections, and low thermal insulation of glass negatively affect. These adverse properties can be significantly reduced utilizing nanotechnological coatings, thus opening up new areas of application for glass such as:

- Improved thermal protection through low-E layers

- Sun protection through a switchable glass tint (e.g., electrochromic)

- Optimized use of daylight through integrated micromirror arrays

- Self-cleaning through photocatalytic coatings

- Anti-reflective layers through nanoporous SiO2 layers

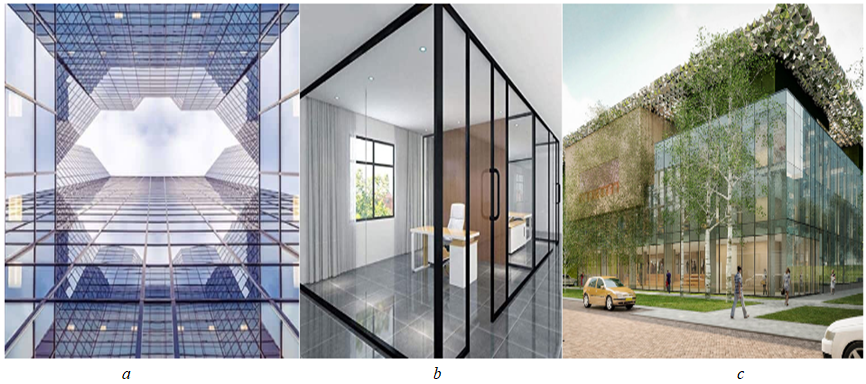

2.1 Smart glass

By using nanotechnology in smart glasses, the amount of light absorption in these glasses can be changed. Smart glasses can control light and heat together, evident in Low-E glass and liquid crystal glasses. Low-E glass refers to glass with a much lower heat transfer than ordinary glass due to the thin layer coated on one side. These glasses can prevent the absorption of unwanted heat caused by light radiation. With nanotechnology in smart energy control glass, glass becomes a beneficial element to reduce energy consumption, increase the building’s brightness and visibility, and the facade’s beauty. Smart glass implements ideas of building with large windows, heavy light, and beauty around the building. These glasses can adjust the color and amount of flow straightforwardly and conveniently. In another type of smart energy control glass, primarily used as a separator in the building’s interior spaces, a thin layer of the liquid crystal is used between the glasses, which becomes transparent by passing electricity through the film. Crystals, by their random orientation in space, scatter light and thus blur the glass. Therefore, millions of dollars can be saved with this system on space heating, cooling, and lighting [13].

Fig. 2 – Different formation of smart glasses

a – liquid crystal layer; b – smart glass (privacy); c – energy-smart glass

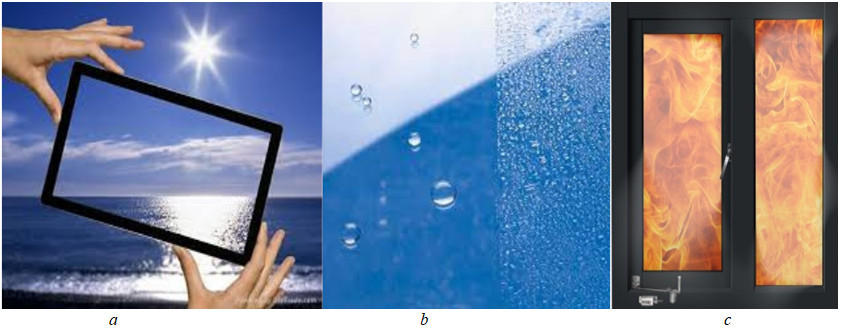

2.2 Anti-reflective glass

In some architectural applications, the reflection of light from the glass is considered an undesirable factor because it reduces the space’s aesthetic quality and thermal comfort. With nanotechnology, anti-reflective glass can be used for applications that require low light reflection and high throughput. Anti-reflective glass has various uses, including its use in the exterior of commercial stores, shop windows, cars, cameras, mobile phones, and mirrors. The process reduces the reflection losses in glass panes from the usual 8% to 2%.

2.3 Anti-dust and anti-fog glasses (self-cleaning)

Self-cleaning glass has been available since 2002. Using nanotechnology, the transparency and cleanliness of these glasses can significantly increase because the combination of self-cleaning and photocatalytic effects helps to decompose bacteria. The quality of self-cleaning in these glasses, which is due to coatings with a thickness of a few nanometers, prevents water vapor droplets’ accumulation on these glasses’ surface and does not interfere with their performance.

2.4 Fireproof glass

Fire protection glass is another achievement of nanotechnology in the glass industry. There are always some negative points for glass to deal with fire, such as fragility, flame, and smoke emission due to melting glass during a fire. Therefore, nanoparticles can be a valuable addition for producing fireproof glass that forms a spatula-like coating due to heat and prevents the glass from breaking. These glasses are almost 50% lighter than previous models, and their fire-retardant effect is twice as much.

Fig. 3 – Types of glasses coated with nanoparticles:

a – anti-reflective glass; b – self-cleaning glass; c – fireproof glass

- Applications of nanotechnology in painting

Nano paints are an innovative type of paint in the reconstruction industry that has given a new concept to material development and creativity. There are different types of nanocoatings paints in the construction industry that can be used in interior and exterior facades, doors, windows, glass, floors, and interior furniture.

3.1 Self-cleaning paints

Self-cleaning anti-paint paints are a group of protective nanocoatings that have received much attention to increasing durability, reducing costs, and reducing the time required to maintain equipment. These dyes can be achieved by adding different types of nanoparticles with the paint resin’s self-cleaning ability. Self-cleaning nano paints do not change the surface’s appearance, are completely transparent, and can be used on the building’s interior and exterior surfaces. In these paints, contaminants or other foreign materials have inferior adhesion to the paint surface, so they are easily removed by natural agents (wind and rain) or surface cleaning.

3.2 Anti-bacterial paints

Anti-bacterial coatings prevent the formation of bacteria, algae, and germs on the surface and protect it against mold and fungus in public places, toilets, kitchens, and food production factories. With nanotechnology and the use of anti-bacterial coatings, inherent anti-bacterial properties are created on surfaces that are not removed by washing or detergents. The patented self-cleaning paint contains nanoparticles of titanium dioxide. When the coating of paint is exposed to the sun or any other ultraviolet light source, any organic substances on the surface decompose with the paint’s coating’s oxidative properties.

3.3 Antistatic paints

Since the generated static electricity by traffic, sliding, and rubbing in various industries where flammable materials are present cause bursts, explosions, irreparable damage, and conductive antistatic coating, the transmission of static electricity in these places is essential. Due to the fillers’ high specific surface area in nano antistatic paints, fewer materials are needed to achieve the desired conductivity. Nano antistatic paints have high mechanical, physical, and chemical properties. This type of paint improves processability, desirable color properties, quality, and very high durability.

3.4 Scratch-resistant paints

Scratches in materials such as wood, metals, plastics, polymers, and glass limits their use in many cases can shorten the life of many products that take a lot of energy and money to replace. Nano scratch coatings are transparent, have a high quality, and can be created on surfaces in form color with transparent layers.

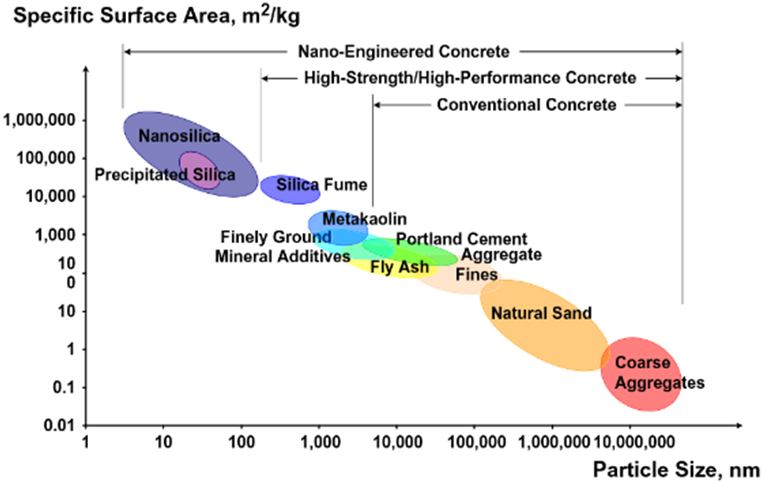

- Concrete

Cement-bound building materials concrete – an artificial rock made from cement, concrete aggregate (sand and gravel or chippings), and water – with an annual production of over 10 billion ton are the world’s most significant economic material in terms of quantity and essential building material in solid and shell construction. The high resistance and strength of concrete are mainly due to crystal structures with only a few nanometers. In recent years, nanomaterials as additives for cement-based building materials and new processes for nanostructure elucidation have provided a platform for significant material improvements in a concrete building. Here, nanotechnologies ensure material enhancements through the use of nanopowders as additives in cement mixes. This improves the strength, workability, and durability of concrete and mortar and conceives other functions such as electromagnetic shielding, thermal protection, thermal conductivity control, color changes, and catalytic reactions in large-scale degradation of pollutants [14], [15], [16], [17]. For instance, nanoscale metal oxides (eg, colloidal silicon dioxide) or block copolymers are already used commercially as nanoscale additives to improve the properties of concrete/mortar. Using colloidal silicon dioxide, which has a particle size distribution typically in size range from 5 to 30 nm, the strength of the concrete and the resistance to acid corrosion can be further improved. The effect is essentially based on a high active surface area of colloidal silicon dioxide (silica) and its ability to form additional strength-increasing reaction products with cement components. The accelerated and more intensive setting reaction and the modified chemical composition of the cement have a positive effect on the microstructure of the concrete. This concrete achieves a steel-like compressive strength of over 200 N / mm2 in the laboratory, even up to 500 N / mm2. Polymer additives act as “spacers,” liquefying and stabilizing cement suspensions, which are used to develop self-compacting concretes. This concrete has improved flowability, adapt optimally to the formwork, and compact the concrete excessively.

Fig. 4 – Particle size and specific surface area related to concrete materials [18], [19]

The recent study on adding nano-SiO2 in cement and concrete showed that both materials had better particle-packing performance [20]. The nano-SiO2 acted as an effective nanofiller for the hydration of calcium silicate in the cement. This nano type can also function as an intense binder that positively changes the cohesion of cement.

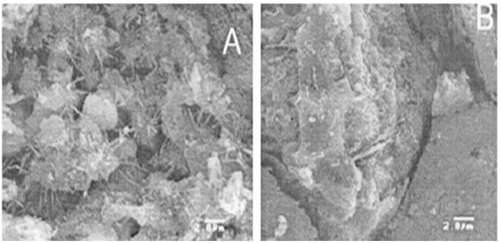

Fig. 5 – SEM plain micrographs (A) and cement paste coated with nano-silica (B) [21]

- Steel

Steel is an essential and widely used material in the building Industry. The strength, corrosion resistance, and welding capability were putting steel on top of the building properties and leveled it as an essential component of the construction industry. The use of nanotechnology in steel helps to improve its physical properties. Today’s steel design to prevent fatigue or damage to steel structures due to its periodic loading, the application of three laws limiting the allowable stress reduction, reducing the service life, and increasing regular visits, applying these restrictions will have a significant impact on costs. And proper use of materials.

Further stresses on the steel cause cracks that lead to rupture and fatigue in the steel. Adding copper nanoparticles to steel reduces its surface roughness and reduces stress resulting in fatigue cracks. Vanadium (V) and molybdenum (Mo) nanoparticles solve the problems of delay rupture associated with high-strength screws, reduce the brittle effect of hydrogen, and improve the quality of steel microstructures. The combination of magnesium and calcium nanoparticles increases the hardness of the weld.

- Energy and lighting technology

Nanotechnologies offer many possibilities for increasing efficiency and developing new types of energy generation and lighting technology in buildings. Due to the low energy consumption, the adjustable color design, and the compact design, LEDs, which are based on nanoscale semiconductor layers, are increasingly being used to set architectural accents in building lighting and facade design. When using colored light, the LED has the advantage that only the required spectrum is generated. On the other hand, with different light sources, coatings or filters are required to produce color, which can absorb 80% of the light produced. In the long term, there are options for new types of lighting technology based on organic light-emitting diodes, which have the potential for large-area, flexible, and electronically controllable multicolor lamps and could thus enable future applications such as luminous wallpapers. The vision of a living environment that can be adapted to the residents’ mood – whether a virtual South Sea beach or a winter landscape – is now within reach thanks to nanotechnology. Dye solar cells are an example of a new class of solar cells that use dyes for light absorption, similar to photosynthesis in nature. The ultra-fast electron transfer principle between a light-absorbing dye complex and a nanocrystalline electrode made of titanium dioxide particles is used.

The greatest challenge for the marketing of dye solar cells lies in their long-term stability for outdoor applications. An airtight seal and a carefully optimized chemical composition of the electrolyte in dye solar cells are required to achieve this goal. The solar efficiency that can be achieved with dye modules in the short and medium-term is 4–5% and thus still well below the efficiency of approximately 15% of conventional solar modules. For a market launch, the specific application advantages of the dye solar cell such as semi-transparency, decorative structuring or combination with electrochemical elements must be implemented. Therefore, the first possible applications are seen in the areas of facades, skylights, sunroofs, and automobiles. Due to the increasing requirements concerning more efficient energy conversion and the trend towards decentralized energy supply, fuel cell systems will also play an essential role in building technology in the future. Here, high-temperature fuel cells are desirable because they allow combined heat and power (CHP) systems to be implemented with a high degree of overall efficiency. The electrical power generation ranges from 1 to 5 kW for single and multi-family houses up to several 100 kW for industrial systems.

Conclusion

Nanotechnology promises significant advances in various scientific and industrial fields, including the construction industry. This technology has provided many opportunities to strengthen the construction industry’s competition, such as faster productivity, reliability, more desirable design, cost-effectiveness, and sustainability. Nanotechnology is helpful in various building parts, including skeletons, facades, building systems, and interior design. Using nanotechnology in the building industry has led to the production and availability of multi-functional building materials with high efficiency and added value while improving the quality, design, and durability of building materials as well as ensuring energy effectiveness. Moreover, this technology has been useful to optimize and increase the performance of existing technologies and introduce a new set of approaches and functions that have not existed before the advent of nanotechnology. Therefore, nanotechnology is a practical novelty and innovative approach in the construction industry, leading to material quality, energy savings, and economic savings.

| Конфликт интересов

Не указан. |

Conflict of Interest

None declared. |

Список литературы / References

- Bhushan B. Springer Handbook of Nanotechnology / B. Bhushan, Springer-Verlag Berlin Heidelberg, 2010. P. 1-2.

- Olar R. Nanomaterials and Nanotechnologies for Civil Engineering / R. Olar // Bulletin of the Polytechnic Institute of Jassy 2011. No 4. – P. 109-118.

- Serrano E. Nanotechnology for sustainable energy / Serrano, G. Rus, J. G. Martínez // Renewable and Sustainable Energy Reviews 2009. No 13. – P. 2373-2384.

- Igarashi K. Nanotechnology for new industry creation and lifestyle creation / K. Igarashi // AIST Tsukuba, 2011. P. – 1-25.

- Nasrollahzadeh S. An Introduction to Green Nanotechnology / M. S. Nasrollahzadeh, S.M. Sajadi, Z. Issaabadi // Interface Science and Technology 2019. No 28. – P. 1-27.

- Zhu W. Application of nanotechnology in construction: Summary of a state-of-the-art report / W. Zhu, P. Bartos, A. Porro // Material Structures 2004. No 37. – P. 649–658.

- Pacheco-Torga Nanotechnology: Advantages and drawbacks in construction and building materials / T. Pacheco-Torga, S. Jalali // Construction and Building Materials 2011. No 25. – P. 582-590.

- Bartos P.J.M. Nanotechnology in Construction: A Roadmap for Development / P.J.M. Bartos // Nanotechnology in Construction 2009. Springer-Verlag Berlin Heidelberg. P. 15-26.

- Whitby R.L.D. Nanomaterials and the Environment: Global impact of tiny materials / R.L.D. Whitby // Smart technologies for water remediation Brighton. P. 1-2.

- Leydecker S. Nano materials in architecture, interior architecture, and design / S. Leydecker, H. Kroto, M. Veith et al. 2008. P. 11-12.

- Khandve V.P. Nanotechnology for Building Material / V.P. Khandve // International Journal of Basic and Applied Research 2013. No 4. – P. 146-151.

- Mauro J.C. Glass: The Nanotechnology Connection / J.C. Mauro, A.J. Ellison, L.D. Pye // International Journal of Applied Glass Science 2013. No 4. – P. 64-75.

- Minko N.I. Nanotechnology in glass materials (review) / N.I. Minko, V.M. Nartsev // Glass and Ceramics 2008. No 65. P. 148–153.

- Teizer J. Nanotechnology and its impact on construction: bridging the gap between researchers and industry professionals / Teizer J. Venugopal M. Teizer W. et al. // Construction Engineering Managanagement. 2011. No 138. –

594–604. - Svintsov A.P. Effect of nano-modified additives on properties of concrete mixtures during winter season / A.P. Svintsov, E.L. Shchesnyak, V.V. Galishnikova et al. // Construction and Building Materials. 2020. No. 237. – 117527.

- Svintsov A.P. Dataset on the effect of nano-modified additives of concrete mixes technological properties for winter concreting / A.P. Svintsov, V.V. Galishnikova, N.A. Stashevskaya // Data in Brief. 2020. No. 31. 105756.

- Urkhanova L.A. Mechanical and electrical properties of concrete modified by carbon nanoparticles / L.A. Urkhanova, S.L. Buyantuev, A.A. Urkhanova et al. // Magazine of Civil Engineering. 2019. No 8. – P. 163-172.

- Sobolev K. How nanotechnology can change the concreteworld:Part 1 / Sobolev K., Ferrada-Gutiérrez, M. // American Ceramic Society Bulleti. 2005. No 84. – P. 14–17.

- Sanchez Nanotechnology in concrete – A review / F. Sanchez, K. Sobolev // Construction and Building Materials. 2010. No 11. P. 2060-2071.

- Patel A. An overview on the application of Nanotechnology in the construction industry / A. Patel, H. Rathod, N. Sharma // International Journal of Innovative Research in Science, Engineering, and Technology. 2013. No 2. – P. 6094–6098.

- Salemi N. Effect of nanoparticles on the durability of fiber-reinforced concrete pavement / N. Salemi, K. Behfarnia // Construction Building Materials. 2013. No 48. – P. 934–941.